Membrane Switch Manufacturer Serving Medical and Defense Industries

Membrane Switch Manufacturer Serving Medical and Defense Industries

Blog Article

Discovering the Production Refine of Membrane Switch for Different Industries

The manufacturing process of Membrane buttons is a complex undertaking that demands precision and focus to detail. From selecting appropriate materials to applying extensive quality assurance steps, each step plays an essential duty in making certain performance. Various sectors, consisting of medical and vehicle, rely upon these elements for their distinct applications. Comprehending the complexities of this process exposes considerable insights right into how these buttons are created and their impact throughout diverse markets.

Comprehending Membrane Changes: A Summary

Trick Materials Utilized in Membrane Switch Manufacturing

In Membrane button manufacturing, the option of vital products significantly affects functionality and durability. Conductive products, adhesives, and coatings play crucial roles, while substratum selection influences overall performance and reliability. Understanding these components is necessary for optimizing the layout and manufacturing of Membrane buttons.

Conductive Materials Review

Conductive products play a vital function in the capability of Membrane switches, making sure dependable electric connections within the gadget. Commonly used materials consist of silver, copper, and carbon-based inks, each offering distinct benefits. Silver is favored for its high conductivity and durability, making it excellent for applications requiring robust performance. Copper, while somewhat much less conductive than silver, is a cost-efficient alternative usually used in published circuits. Carbon-based inks offer a flexible choice, suitable for applications where flexibility and lower costs are focused on, although they have lower conductivity compared to steel alternatives. The choice of conductive products straight affects the general integrity, lifespan, and performance of the Membrane button, making it an essential factor to consider in the production procedure.

Adhesives and Coatings

Coverings and adhesives are crucial elements in the production of Membrane switches, giving essential bonding and protective properties. These products ensure that various layers of the button, consisting of graphic overlays and circuitry, stick securely to one another, enhancing sturdiness and performance. Frequently made use of adhesives consist of pressure-sensitive adhesives (PSAs) and epoxy-based formulations, which provide solid adhesion and strength. Coatings, such as polyurethane or acrylic, serve to secure against environmental elements, consisting of wetness, abrasion, and chemicals. Furthermore, finishes can improve responsive comments and aesthetic appeal, contributing to the overall user experience. The option of proper adhesives and coatings is critical for maximizing performance and long life in varied applications across various markets, guaranteeing that Membrane switches fulfill particular functional demands.

Substratum Selection Variables

Substrate option plays a crucial duty in the manufacturing of Membrane switches, as it substantially affects their overall efficiency and durability. Trick products such as polyester, polycarbonate, and versatile published circuit card (FPCBs) are commonly made use of for their distinctive homes. Polyester is favored for its cost-effectiveness and resistance to abrasion, making it suitable for applications with high wear. Polycarbonate offers remarkable quality and impact resistance, ideal for environments needing high visibility. FPCBs supply enhanced adaptability and are often made use of in intricate styles. The choice of substratum additionally affects variables like thermal stability, chemical resistance, and ease of printing. Inevitably, choosing the appropriate substratum is important for guaranteeing the performance and long life of Membrane switches over throughout different markets.

The Design Refine of Membrane Switches Over

The design process of Membrane switches is a crucial stage that considerably influences the performance and aesthetic appeals of the last item - membrane switch manufacturer. It begins with specifying the certain requirements of the application, including dimensions, switch design, and tactile comments preferences. Designers should consider user communication, ensuring that the button is user-friendly and accessible.Next, materials are selected based upon toughness, flexibility, and ecological resistance. The combination of graphics and branding aspects is additionally crucial, as it enhances visual charm and interaction. Prototyping permits for iterative screening, enabling changes based on customer comments and performance evaluations.Additionally, the design has to make up the electric parts, such as ports and circuits, making certain reliability and ease of usage. Eventually, a successful layout integrates performance, looks, and customer experience, leading the method for efficient production and resilient performance in numerous sectors

Printing Methods for Membrane Switches

The printing strategies used in Membrane button manufacturing play a vital role in establishing the end product's high quality and performance. Display printing provides advantages such as durability and vibrant shade application, while digital printing advancements provide adaptability and precision in style. Comprehending these methods can considerably impact the general effectiveness of Membrane switches in different applications.

Display Printing Benefits

Countless benefits make display printing a preferred technique for creating Membrane buttons. This method permits top quality, thorough layouts and lively shades, which are essential for user interface applications. Screen printing is specifically reliable for using thick ink layers, boosting sturdiness and tactile responses. Additionally, it uses exceptional attachment to numerous substratums, guaranteeing long life in requiring atmospheres. The procedure is economical for big manufacturing runs, as it decreases arrangement time and waste. Moreover, screen printing sustains a wide variety of inks, consisting of specialty and UV-curable alternatives, making it possible for adaptability in design. Its ability to generate consistent results website link across numerous systems makes it a trustworthy choice for manufacturers going for top quality and effectiveness in Membrane button production.

Digital Printing Innovations

Advancements in electronic printing modern technology are changing the production of Membrane switches, using manufacturers cutting-edge services that boost design adaptability and effectiveness. Digital printing permits complex layouts and high-resolution graphics, allowing custom branding and performance without the constraints of standard techniques. This technique lowers setup times and expenses, helping with much shorter manufacturing runs and very little waste, making it perfect for organizations with varying demands. In addition, advancements in ink formulas provide much better longevity and adhesion, making sure long life in various environments. As industries increasingly look for personalized and complicated layouts, digital printing stands apart as a crucial technique, setting a brand-new standard in Membrane button manufacturing. The integration of these technologies placements manufacturers to meet progressing market requires efficiently.

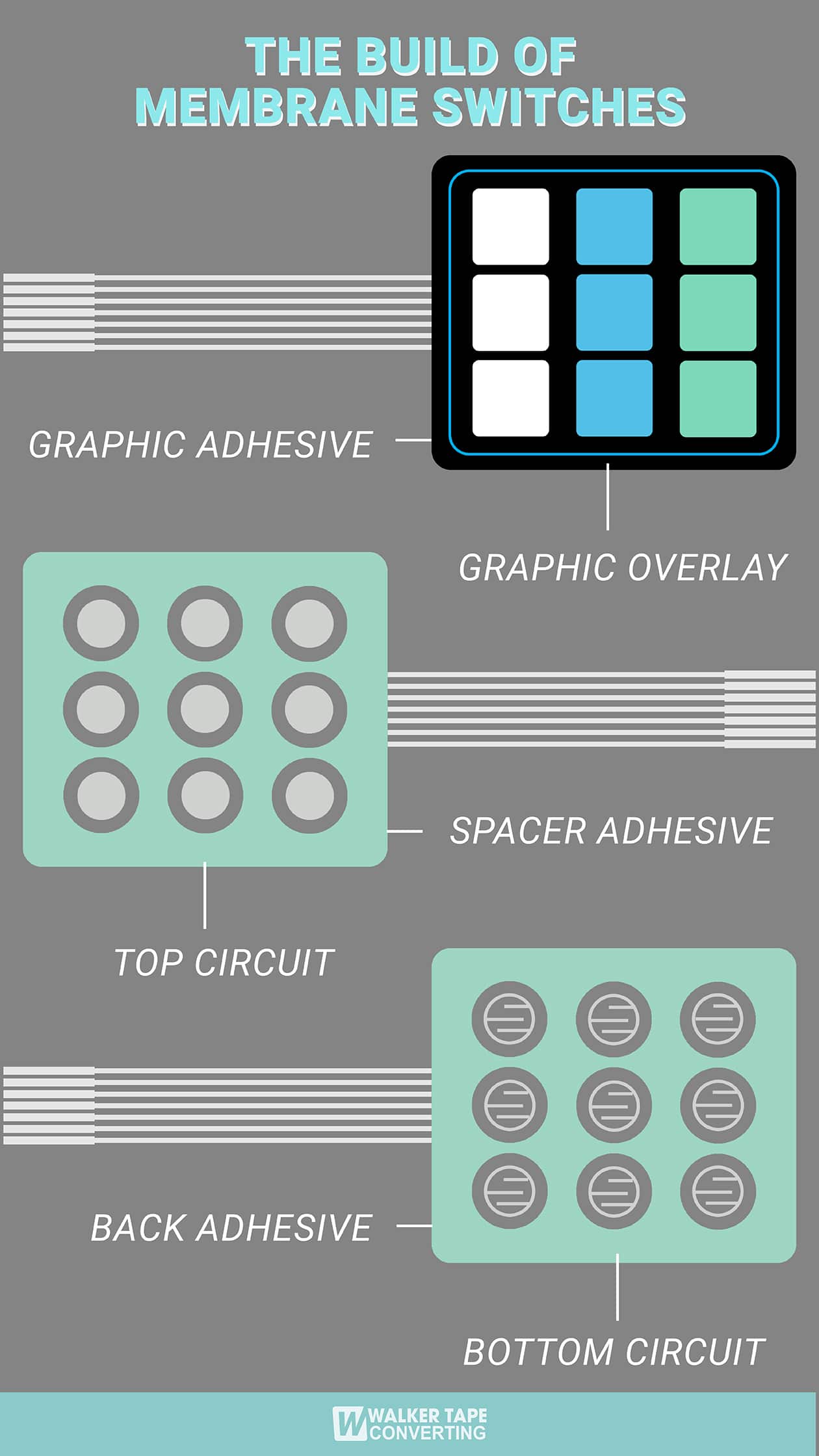

Assembly and Layering of Membrane Switch Components

Careful assembly and layering of Membrane switch elements are vital to guaranteeing performance and durability. This process starts with the precise placement of numerous layers, consisting of the visuals overlay, sticky, circuit layer, and backing product. Each element should be very carefully placed to keep electrical integrity and interface responsiveness.During assembly, conductive traces are used to the circuit layer, normally made from materials like polyester or polycarbonate. This layer is vital, as it transmits signals when pressure is applied. The glue utilized for bonding these layers is likewise chosen for its capability to sustain ecological tensions while maintaining a safe and secure bond.Heat and stress are frequently used throughout the setting up process to identify that the layers stick appropriately without jeopardizing the functionality of the button. Attention is provided to the edge sealing to shield against dampness and pollutants, securing the durability of the Membrane button in different industrial applications.

Top Quality Control Measures in Membrane Switch Production

Quality control actions play a vital function in making hop over to these guys certain the integrity and performance of Membrane switches adhering to the setting up and layering of their components. In the production procedure, several vital evaluations are performed to copyright top quality requirements. These consist of visual evaluations for issues in printing and sticky application, as well as useful examinations to verify the responsiveness of each switch.Additionally, environmental screening is carried out to examine the buttons' toughness versus temperature fluctuations and humidity direct exposure. Manufacturers often carry out analytical procedure control (copyright) strategies to keep track of manufacturing uniformity, enabling early detection of anomalies.Furthermore, traceability systems are established to track components and materials, guaranteeing liability and helping with recalls if required. Calibration of tools and adherence to sector criteria are additionally crucial to preserving item integrity. Jointly, these quality control steps protect the performance of Membrane changes across different applications, ultimately enhancing customer fulfillment.

Applications of Membrane Changes Across Different Industries

Membrane switches are made use of throughout a diverse array of industries, showcasing their versatility and flexibility. In the clinical sector, they provide dependable and waterproof interfaces for tools such as diagnostic tools and mixture pumps, guaranteeing hygiene and ease of usage. The vehicle market employs Membrane buttons for dashboard controls, making it possible for seamless interaction between the vehicle driver and automobile systems.In customer electronic devices, these switches are found in devices and handheld tools, providing a sleek, modern-day visual while enhancing capability. Industrial applications likewise leverage Membrane changes for machinery control board, where resilience and resistance to harsh problems are essential.Furthermore, the aerospace and defense industries make use of Membrane buttons for cockpit instrumentation and interaction systems, focusing on reliability and efficiency under extreme conditions. Overall, Membrane switches play a critical duty in enhancing the user experience and operational performance throughout different domains.

Often Asked Questions

For how long Does It Take to Produce a Membrane Layer Switch?

The production time for a membrane button generally varies from a couple of days to a number of weeks - membrane switch manufacturer. Factors affecting this duration include style intricacy, material schedule, and production volume, learn this here now all affecting the general timeline markedly

What Is the Normal Life-span of a Membrane Switch?

The common life-span of a membrane layer switch typically ranges from 1 to 5 million actuations, depending on aspects such as worldly top quality, environmental conditions, and use regularity, significantly affecting toughness and total performance.

Can Membrane Switches Over Be Custom-made for Details Applications?

Membrane buttons can without a doubt be customized for specific applications. Their design versatility enables alterations in size, form, shades, and graphics, ensuring compatibility with special demands throughout various industries and improving performance and individual experience.

Are Membrane Switches Over Eco-friendly?

The environmental effect of Membrane switches over varies. Some materials utilized might not be environmentally friendly, while advancements in producing procedures are significantly focusing on sustainability, intending to lower waste and promote recyclable elements in their manufacturing.

What Are the Common Failure Modes of Membrane Switches?

Common failure modes of Membrane buttons consist of delamination, glue failing, damage from use, dampness access, and electrical failures. These problems can substantially affect functionality, performance, and life-span in numerous applications throughout different industries. Membrane buttons can be customized to fit particular style demands, such as shape, functionality, and size, making them very adaptable.The construction normally entails numerous layers, consisting of a visuals overlay, adhesive, and a circuit layer, which work together to create a seamless customer experience. In Membrane button manufacturing, the option of essential materials considerably affects capability and durability. The automotive sector uses Membrane switches for control panel controls, making it possible for smooth communication in between the motorist and automobile systems.In consumer electronics, these buttons are found in home appliances and handheld devices, supplying a streamlined, modern aesthetic while boosting capability. Industrial applications likewise take advantage of Membrane switches for machinery control panels, where resilience and resistance to harsh problems are essential.Furthermore, the aerospace and defense markets use Membrane buttons for cockpit instrumentation and interaction systems, focusing on dependability and performance under severe conditions. Membrane buttons can certainly be customized for details applications.

Report this page